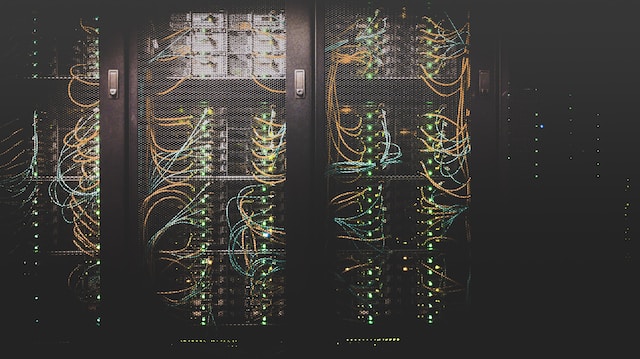

Today’s electronics systems have a lot of wires that are brought into rack enclosures. These require special care to prevent accidental damage.(Rack Systems Cabling)

Cable management accessories can help route and organize these cables to installers’ specs.

Increased Efficiency

A tangled mess of cables is every data center tech’s worst nightmare. Effective rack cabling keeps cables organized and out of the way to enable easier access for maintenance and troubleshooting.

The streamlined look also helps reduce the risk of damage to expensive equipment. Structured cable management can also make moves, adds, and changes quicker and more efficiently.

Rack system accessories like vertical cable managers provide structured vertical cable management that promotes a clean and organized patch cord and general cabling system while maintaining bend radii. These products also eliminate the need for horizontal cable management panels and can improve airflow in racks. Column protectors, or pallet rack guards, are another option to protect the structural integrity of rack columns in warehouses with heavy forklift traffic.

Increased Security

When rack systems Nashville cabling is organized, it allows easy access to components for serviceability. It also reduces downtime and lost work time during problem resolution or hardware upgrades.

Server rack cable management helps ensure that cables don’t obstruct airflow, essential for equipment performance and cooling efficiency. It can also help keep cables away from sharp edges on equipment or other surfaces that could puncture them. Protective accessories like brushed grommet cable seals can be used to reduce friction.

Stack racks with organized wiring can be more easily moved or replaced, which is essential for reducing downtime and ensuring your business can grow. They can also be locked to prevent tinkering and other unauthorized activity. This is especially critical in environments where security footage may be stored on a stack rack.

Reduced Downtime

Today’s electronic systems have various types of wiring, including data, audio, video, security, and control. Managing these different signals and cables is crucial to system availability as the system scales up and down.

Cluttered cabling can lead to equipment failure due to excessive heat. It’s also difficult to troubleshoot problems through a jungle of tangled wires. Effective rack cable management reduces downtime by allowing more accessible access to individual components and devices and improving airflow, cooling, and maintenance efficiency.

Rack and stack system accessories help to keep cables organized and out of critical airflow paths and prevent blockages that may cause heat build-up and other device failures. These products also maintain proper bend radius and prevent stress on the wires, which can lead to cable damage.

Increased Flexibility

Whether the project calls for expansion, equipment replacement, or moving, an adequately configured rack system makes it easier to handle these changes. This is especially important for network cabling, as a messy, unorganized wire environment can lead to downtime and human error.

Correct cable management techniques also allow for flexibility in internal wiring layouts, ensuring proper bend radius for cables and separating signal and power lines to prevent voltage drops. This includes segregating AC cables from speaker wires and keeping them away from close parallel runs, which can cause heat build-up and shorten lifespan.

Other helpful practices include using a color code, labeling both ends of each cable, and routing cables through the side of the rack rather than underneath. These simple tasks can significantly reduce the chance of wire damage.

Increased Efficiency

Using properly-dressed racks helps your command center installation run smoothly. It prevents electromagnetic interference caused by crowded and tangled cables and provides easier access to power, network, and data connections.

Organizing racks helps maintain proper bend radius for twisted-pair and coax cables. It also makes it easy to install new equipment and make changes or additions in the future.