In the fast-paced world of product development, efficiency is crucial. Rapid prototyping has emerged as a game-changer, enabling accelerated iterations and faster time-to-market. In this article, we will explore the importance of rapid prototyping in plastic injection molding, particularly in the context of China custom injection molding. With a focus on clear injection molded plastics and their unique challenges, we will delve into how rapid prototyping is revolutionizing the product development process.

The Benefits of Rapid Prototyping in Custom Injection Molding

Rapid prototyping offers several benefits in the context of custom injection molding, especially in China, a hub for manufacturing. It allows for quick and cost-effective production of prototypes that closely resemble the final product, enabling designers and engineers to evaluate form, fit, function, and aesthetics before moving forward with full-scale production. This reduces the risk of errors, saves time, and minimizes costly design changes later in the process.

Accelerating Iterations and Time-to-Market

One of the primary advantages of rapid prototyping in custom injection molding is its ability to accelerate iterations and reduce time-to-market. Traditional manufacturing processes often involve lengthy lead times and costly tooling modifications. However, with rapid prototyping, designers can quickly produce functional plastic prototypes, allowing for faster design iterations and more efficient problem-solving. This significantly speeds up the product development cycle, enabling businesses to bring their products to market ahead of the competition.

Validating Designs and Improving Manufacturability

Clear injection molded plastics present unique challenges due to the need for transparency and optical clarity. Rapid prototyping allows designers to create clear prototypes that closely mimic the attributes of the final product, such as transparency, surface finish, and light transmission. By validating the design early in the process, China custom injection molding companies can identify potential issues related to molding, tooling, or assembly and make necessary modifications to improve manufacturability and optimize the final product.

Cost-Effective Design Optimization

Rapid prototyping plays a crucial role in cost-effective design optimization. By producing prototypes quickly and at a lower cost compared to traditional methods, designers can explore multiple iterations, perform functional testing, and gather valuable feedback from stakeholders. This iterative approach enables them to refine the design, optimize material usage, and enhance injection molding efficiency. China custom injection molding companies can leverage rapid prototyping to identify opportunities for cost reduction, eliminate design flaws, and improve overall product quality, ultimately leading to better cost-effectiveness.

Enhancing Communication and Collaboration

Effective communication and collaboration are essential for successful product development. Rapid prototyping facilitates clearer communication between designers, engineers, manufacturers, and clients by providing a tangible representation of the product. Visualizing and testing a physical prototype helps all stakeholders to understand the design intent, functionality, and potential improvements. This enhances collaboration, reduces misinterpretation, and leads to more efficient decision-making throughout the development process.

Overcoming Challenges in Clear Injection Molded Plastics

Clear injection molded plastics, such as those used in medical devices, optical components, or consumer electronics, have specific challenges due to their optical requirements. These challenges include achieving optical clarity, minimizing blemishes, managing internal stresses, and ensuring dimensional accuracy. Rapid prototyping allows China custom injection molding companies to test and refine the clear plastic injection molding process, ensuring the final product meets the strict quality standards for clarity and functionality.

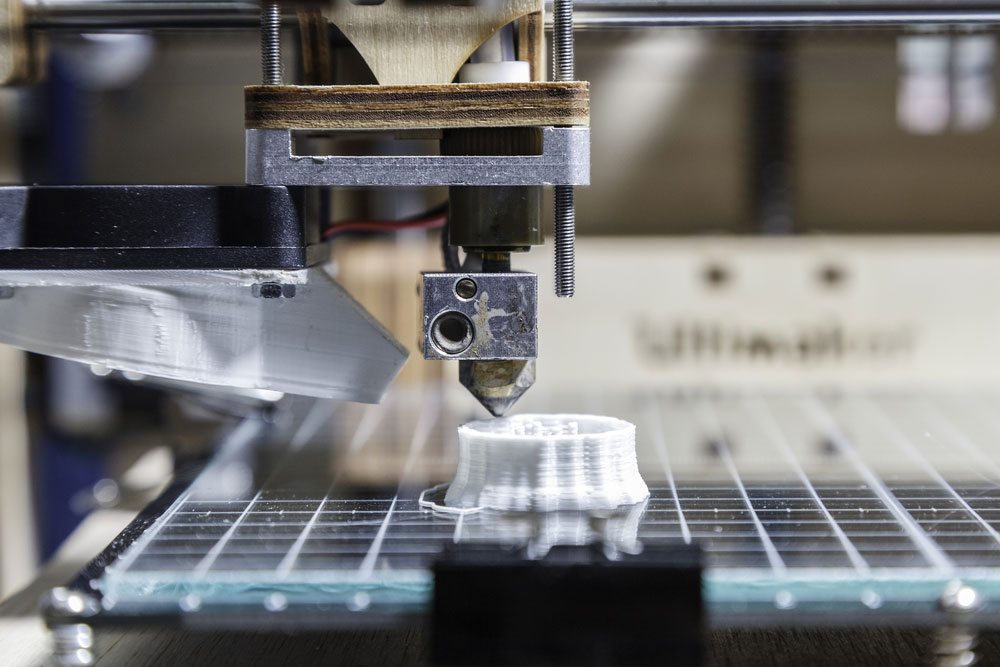

Choosing the Right Rapid Prototyping Method

Several rapid prototyping methods are available for custom injection molding, including 3D printing, CNC machining, and vacuum casting. The choice of method depends on various factors such as the desired accuracy, material characteristics, complexity of the design, and production volume requirements. Collaborating with a China custom injection molding company experienced in rapid prototyping enables businesses to select the most appropriate method for their specific project, ensuring optimal results.

Conclusion

Rapid prototyping has revolutionized the product development process in custom injection molding, particularly in China. By accelerating iterations, reducing time-to-market, validating designs, optimizing manufacturability, and enhancing communication and collaboration, rapid prototyping plays a vital role in cost-effective and efficient product development. In the context of clear injection molded plastics, rapid prototyping enables businesses to overcome the unique challenges related to optical clarity and dimensional accuracy. By leveraging the benefits of rapid prototyping and collaborating with experienced China custom injection molding companies, businesses can streamline their product development process, improve the quality of their final products, and gain a competitive edge in the market.