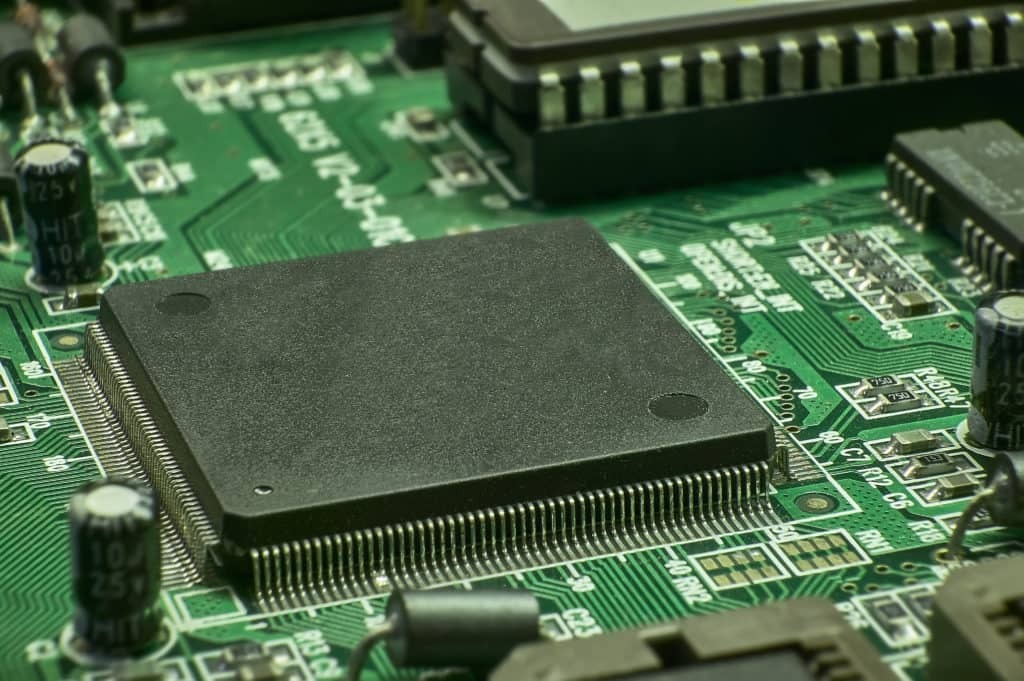

A printed circuit board, or PCB, is a thin board made of fiberglass, composite epoxy, or other laminate material. They are used in a variety of electronics, from simple circuits to complex ones used in computers and other digital devices. PCBs are an essential component of many electronic devices, as they provide the support and connectivity needed for the proper functioning of the circuit. Visit https://www.pcbasic.com/ for more information.

What is PCB?

PCB, or Printed Circuit Board, is a thin board made of different materials, used to connect electronic components using conductive tracks, pads, and other features. They are found in a wide range of electronic devices, from simple hobby kits to complex scientific instruments.

PCBs are used to mechanically support and electrically connect electronic components using conductive tracks, pads and other features etched from copper sheets laminated onto a non-conductive substrate. A PCB can be single sided, double sided (two copper layers) or multi-layer (outer and inner layers).

The tracks on the PCB are usually printed on both the top and bottom layers. The tracks on the top layer are connected to the tracks on the bottom layer using vias (holes drilled through the PCB). This allows electrical signals to be routed between the different layers of the PCB.

PCBs are manufactured using a number of different processes, the most common of which are described below.

Photolithography

Photolithography is the process of creating patterns on a photosensitive material using light. A photosensitive material is one that changes its properties when exposed to light.

In the case of PCBs, the photosensitive material is a film of light-sensitive chemicals called a photoresist. The photoresist is applied to the surface of the PCB and then exposed to light through a mask. The mask is a template that has the desired pattern of tracks and other features etched into it.

The exposed photoresist is then developed, which means that the parts of the photoresist that were exposed to light are removed. This leaves the desired pattern of tracks and other features on the surface of the PCB.

The tracks and other features are then etched into the PCB using chemicals. The etching process removes the exposed copper, leaving the desired tracks and other features on the PCB.

Plating

Plating is a process that involves coating the surface of the PCB with a thin layer of metal. This is usually done using a process called electroplating.

In electroplating, the PCB is placed in a solution that contains metal ions. An electric current is passed through

What are the benefits of using PCB?

PCBs are used in a variety of electronic devices for a variety of reasons. Some of the benefits of using PCBs include:

1. Increased Reliability

PCBs are much more reliable than other methods of electronic assembly, such as point-to-point wiring. This is because PCBs are designed to withstand repeated use and abuse.

2. Reduced Size

PCBs can be made very small, which is ideal for portable electronic devices.

3. Reduced Weight

PCBs are also very lightweight, which is another advantage for portable electronic devices.

4. Reduced Cost

PCBs are less expensive to manufacture than other methods of electronic assembly.

5. Increased Efficiency

PCBs are more efficient than other methods of electronic assembly because they allow for more components to be placed in a smaller area.

6. Increased Functionality

PCBs can be designed to perform multiple functions, such as providing power to a device and providing a data storage medium.

Why is PCB used in electronics?

PCB, or Printed Circuit Board, is a thin board made of non-conductive material, on which thin lines of conductive material are printed. These conductive lines connect different electronic components on the board, making it possible for them to communicate with each other.

Why is PCB used in electronics?

There are several reasons for why PCB is used in electronics. First of all, it is a very efficient way to connect electronic components. The thin lines of conductive material can be printed very precisely, meaning that the connection between different components can be very tight. This results in a more reliable connection, and less chance for error.

Another reason why PCB is used in electronics is that it is very lightweight. This is important in many electronic devices, where weight is a major factor. For example, in laptop computers and mobile phones, every gram counts.

Finally, PCB is also very cost-effective. When mass-produced, the cost of a PCB can be very low. This makes it an attractive option for many electronic manufacturers.

How does PCB work?

A printed circuit board (PCB) is a board made of one or more layers of a conductive material, such as copper, that are used to connect electronic components using conductive tracks, pads, and other features etched from one or more sheet layers of copper laminated onto and/or between non-conductive substrates.

PCBs are found in almost all types of electronic devices, from your computer’s motherboard to your cell phone’s circuit board. They are used in everything from the simplest electronic devices to the most complex.

How does a PCB work?

A PCB is essentially a board that holds all of the components of an electronic device in place. The tracks on the PCB are used to connect the different components together. These tracks are made of a conductive material, such as copper, and are etched onto the board.

The pads on a PCB are used to connect the tracks to the components. The pads are also made of a conductive material, such as copper, and are attached to the tracks.

The vias on a PCB are used to connect the different layers of the board together. Vias are also made of a conductive material, such as copper, and are drilled through the board.

How are PCBs made?

PCBs are made using a process called photolithography. In this process, a light-sensitive material is used to create the tracks and pads on the board. The light-sensitive material is exposed to a light source, which creates a negative image of the tracks and pads.

The exposed light-sensitive material is then developed, which creates a positive image of the tracks and pads. The tracks and pads are then etched onto the board.

The vias are then drilled into the board. The board is then covered with a solder mask, which protects the tracks and pads from being soldered to the wrong components.

The board is then covered with a silkscreen, which is used to print the component values and other information onto the board.

The board is then covered with a solder resist, which protects the tracks and pads from being soldered to the wrong components

What are the different types of PCB?

PCB or Printed Circuit Board is a board that connects electronic components using copper tracks. It is used in almost all electronic devices. The three main types of PCB are Single-sided, Double-sided, and Multilayer.

Single-sided PCBs are the most basic type and have tracks on only one side of the board. They are used in simple electronic devices such as calculators. Double-sided PCBs have tracks on both sides of the board and are used in more complex devices such as computers. Multilayer PCBs have multiple layers of tracks and are used in very complex electronic devices such as smartphones.

PCBs are used in electronic devices because they are very reliable and can be mass-produced. They are also very small, which makes them perfect for use in portable electronic devices.

How to choose the right PCB for your project?

PCBs, or Printed Circuit Boards, are an integral part of electronic devices and circuits. They provide a way to connect electronic components and ensure that they function correctly. There are many different types of PCBs available, and choosing the right one for your project can be a challenge. Here are some things to consider when choosing a PCB:

1. The first thing you need to consider is the size of the PCB. You need to make sure that the PCB you choose is large enough to accommodate all of the electronic components you need to use.

2. The next thing you need to consider is the material the PCB is made from. The most common materials used for PCBs are FR-4 and FR-5. FR-4 is a glass-reinforced epoxy laminate that is flame-retardant. FR-5 is a similar material, but it has a higher dielectric constant, which makes it better suited for high-frequency applications.

3. You also need to consider the thickness of the PCB. The thickness of the PCB affects the amount of heat that the PCB can dissipate. If you are using a lot of power-hungry components, you will need a thicker PCB to dissipate the heat.

4. Another important factor to consider is the copper thickness. The copper thickness determines the amount of current that the PCB can handle. If you are using high-powered components, you will need a thicker copper layer.

5. The final factor to consider is the surface finish. The surface finish of the PCB affects the solderability of the PCB and the resistance to corrosion. The most common surface finishes are HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel/Immersion Gold).

These are just a few of the things you need to consider when choosing a PCB. If you take the time to consider all of these factors, you will be able to choose the right PCB for your project.